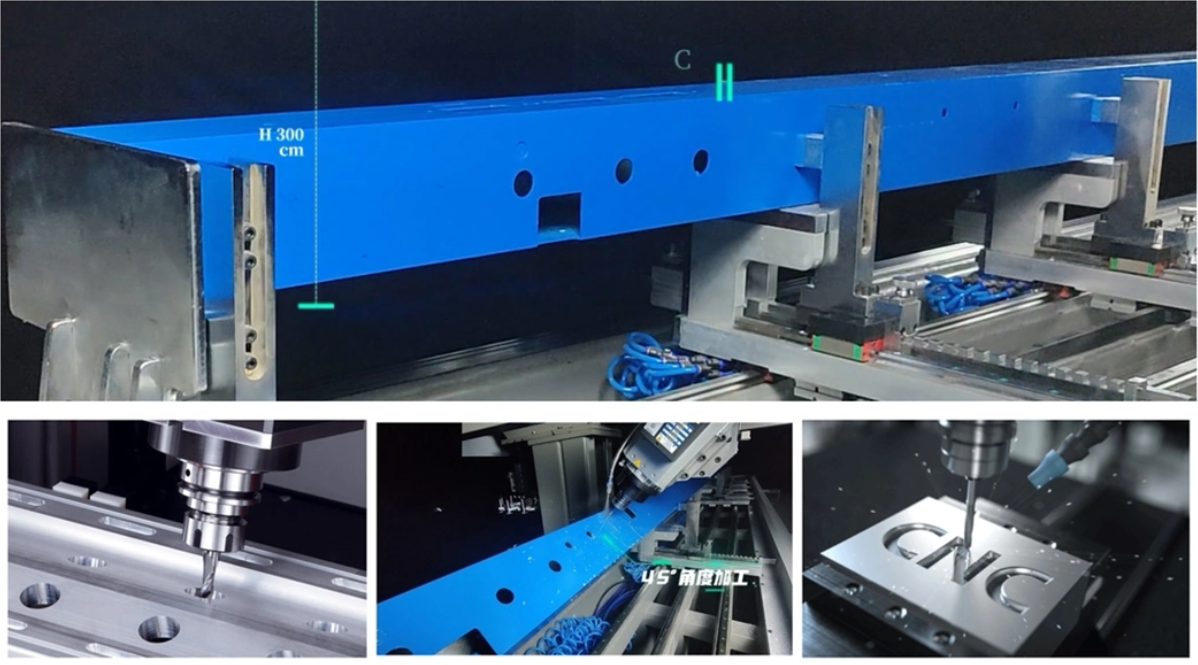

Automatic Aluminum CNC Milling Drilling Machine 4 Axis CNC Machining Center

| Power supply | 380V/3Phase/50Hz or customized |

| Spindle power | 12kW |

| Maximum speed | 24000/min |

| Air pressure | 0.6~0.8Mpa |

| Spindle taper hole | ISO-30 |

| Tool magazine form | rotary tool magazine |

| Tool magazine capacity | 12 |

| X/Y/Z axis stroke | 7000mm/1500mm/600mm |

| X axis feeding speed | 0~55m/min |

| Y/Z axis feeding speed | 0~40m/min |

| X-axis servo motor | 1.8KW |

| Y-axis servo motor | 0.85KW |

| Z-axis servo motor | 1.3KW |

| Rotary tool magazine servo motor | 400W |

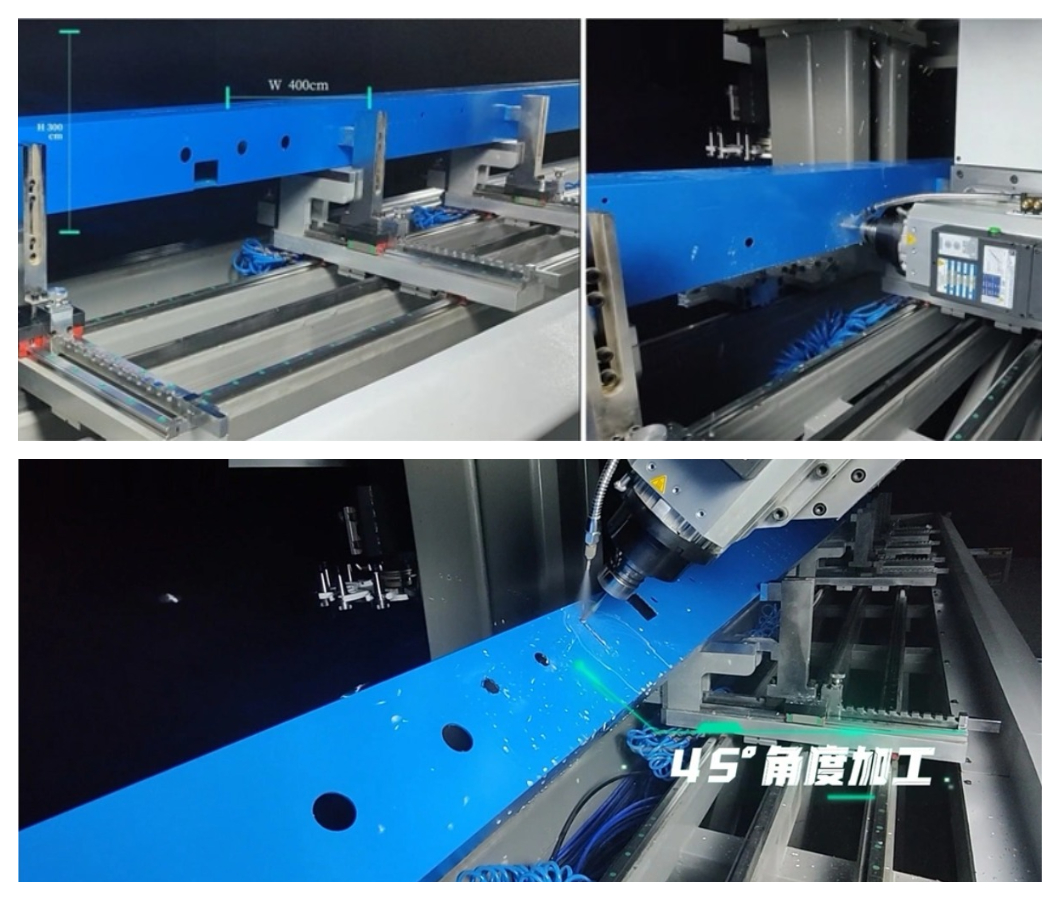

| C-axis rotation range | ±110º |

| Processing length | 7000mm |

| Processing width | 400mm |

| Processing height | 300mm |

| Repeat positioning accuracy | ±0.05mm |

| Machining accuracy | ±0.1mm/m |

| Overall dimension | 9800×2500×2800mm |

| Weight | 4500kg |

Features

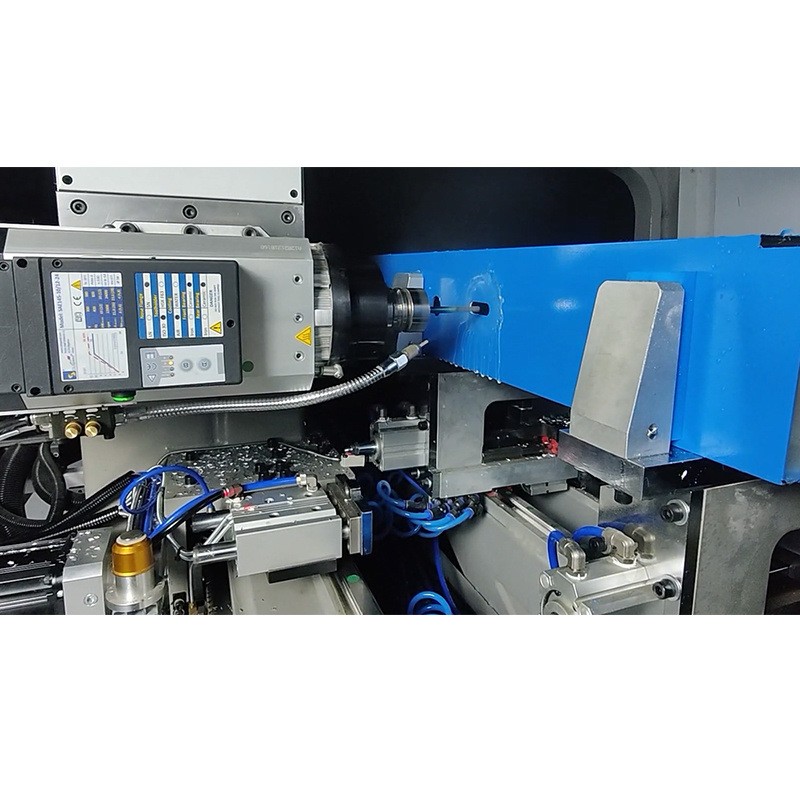

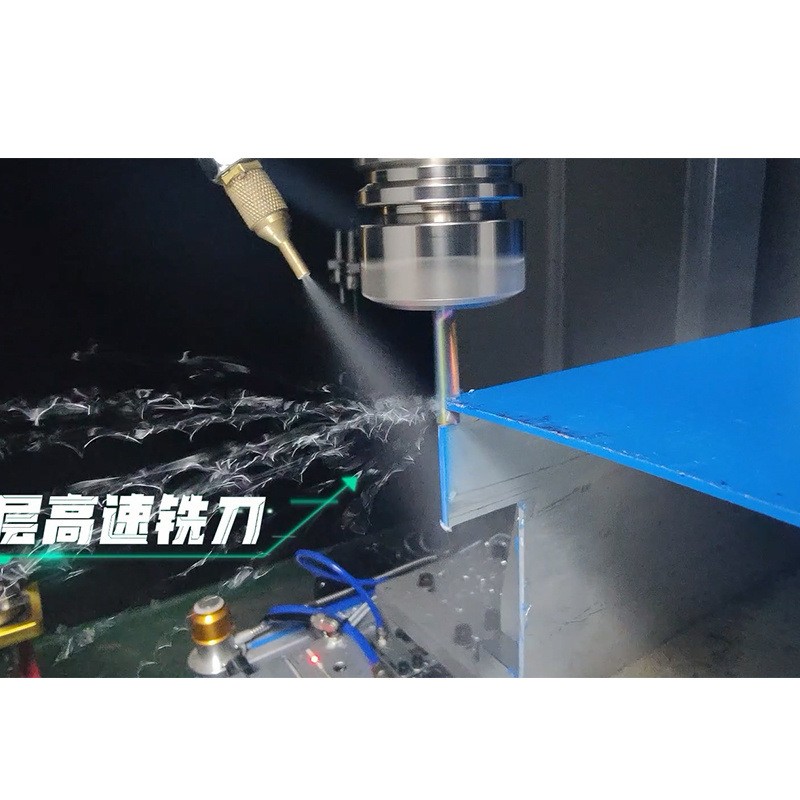

1. This machine can realize one-time clamping of raw materials, and complete multi-process processing such as milling keyhole grooves, flow grooves, air pressure balance holes, and installation holes according to processing needs.(Programming customization)

2. The machine adopts Shenzhen Han's (PA) machine tool numerical control system, which can complete continuous automatic milling of profiles of different specifications and sizes, with powerful functions.

3. CAD drawings can be imported into the system conveniently and easily, and can be connected to domestic and foreign window and door and curtain wall system software such as German Klaes, Chuangao, Duter, Singer Schüco, Changfeng, etc.

4. It is suitable for the processing of complex parts such as various aluminum, copper, PVC, industrial profiles, building curtain walls, sun rooms and so on.

5. High-quality imported servo motors, ball screws, linear guide pairs and bearings are used to ensure that the machinehas high machining accuracy, high stability and reliability. The feed movement is pre-stretched to ensure stable machining accuracy.

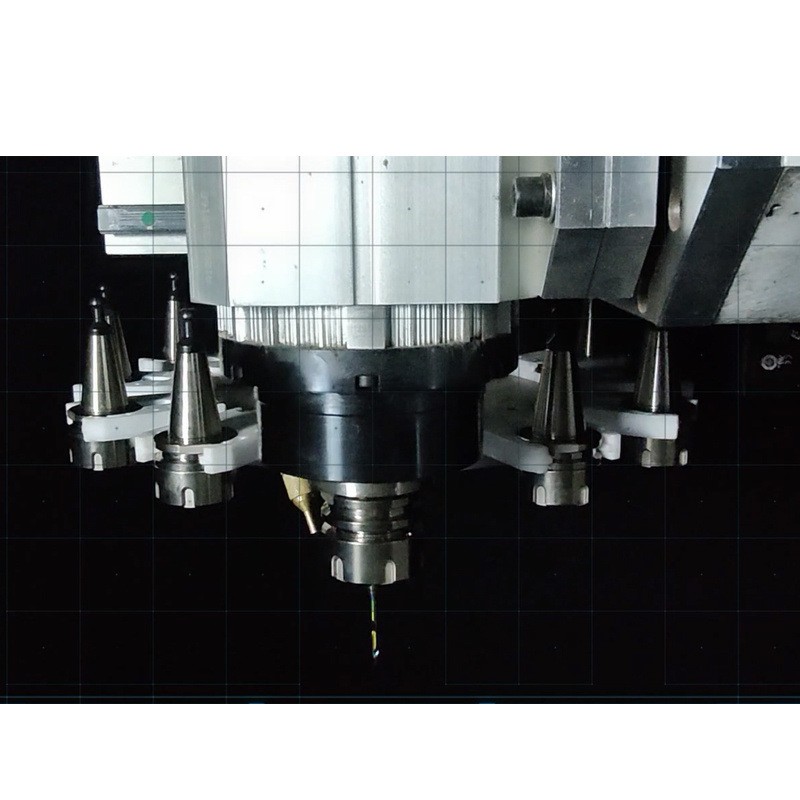

Tool magazine

Sample Photos

Packing Details

Company Profile

Shandong Maichen CNC Machinery Co.,LTD. is a leading enterprise in building Windows and doors and building glass industry, specializing in manufacturing complete sets of building energy-saving plastic windows and doors machines, aluminum alloy windows and doors machines, insulating glass machines, curtain wall machines. The company was founded in 2005, the products all over China's provinces, cities, autonomous regions, and exported to the United States, Europe, Russia, Nigeria, the United Arab Emirates, Brazil, India and other more than a dozen countries. We strictly in accordance with the ISO9001:2000 version of the international quality certification system, manufacturing quality, safety, standard of high quality products to get the best evaluation from customers, with good customer reputation to increase the annual turnover is our sales strategy.

The company has riveting welding workshop, mechanical processing, painting workshop, assembly workshop, exhibition hall, warehouse, covering an area of more than 30 mu, can be customized according to customer requirements and production needs of non-standard equipment. Precision mechanical parts, rigorous assembly attitude, perfect after-sales service for every customer escort. More than 30 kinds of aluminum window processing machines can complete the cutting, Angle group, drilling, punching, bending round process of aluminum profiles; More than 20 kinds of plastic doors and windows processing machines can complete plastic profiles cutting, welding, milling, cleaning procedures; More than 20 kinds of insulating glass processing machines and glass curtain wall machines can complete the cutting, cleaning, heating, gluing, cold pressing, edging, assembly and filling processes of slot-aluminum insulating glass or composite adhesive strip insulating glass. Due to the difference of production scale and efficiency, we can provide customers with the factory plan, cost accounting and the latest industry information according to the most reasonable set of industrial line assembly line operation according to your output ratio. In order to make your installation and use more safe, convenient, fast and efficient work, we have arranged professional engineers to do after-sales technical guidance, troubleshooting and other technical problems for you.

Our Advantages

SHANDONG MAICHEN CNC MACHINERY

SHANDONG MAICHEN CNC MACHINERY