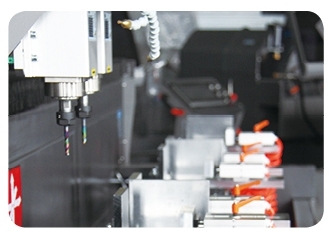

1. High-precision processing: Controlled by a CNC system, it can achieve precise drilling and milling operations, with high processing accuracy and small errors. For example, when processing precision molds, it can ensure that the size and shape of the parts meet extremely high precision requirements.

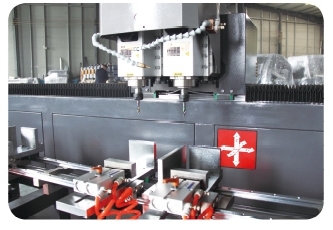

2. High degree of automation: Operators only need to input programs and parameters, and the machine can automatically complete the processing process, reducing manual intervention and improving production efficiency.

3. Versatility: It can not only perform drilling but also milling, and can complete various processes such as complex contour processing and surface processing.

4. Flexible programming: It supports multiple programming methods, such as manual programming and computer-aided programming, to meet processing requirements of different complexities.

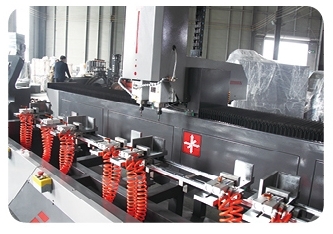

5. Good stability: It has a good structural design and high-quality components, and can maintain a stable working state during long-term operation, ensuring the consistency of processing quality.

6. Convenient operation: Equipped with a user-friendly operation interface, it makes it easier for operators to master and operate.

7. Efficient production: The fast spindle speed and feed speed greatly shorten the processing time and improve production efficiency.

8. Wide range of applications: It can process various materials, including metals, plastics, composite materials, etc.

In conclusion, CNC drilling and milling machines have been widely used in the field of mechanical processing due to their characteristics of high precision, high automation, versatility, and high efficiency.

SHANDONG MAICHEN CNC MACHINERY

SHANDONG MAICHEN CNC MACHINERY