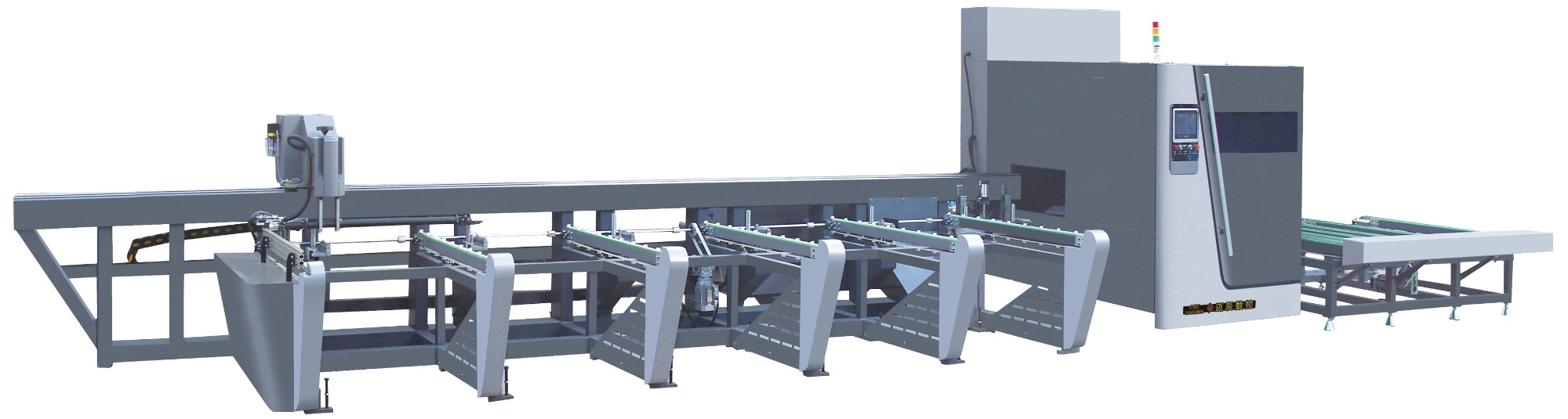

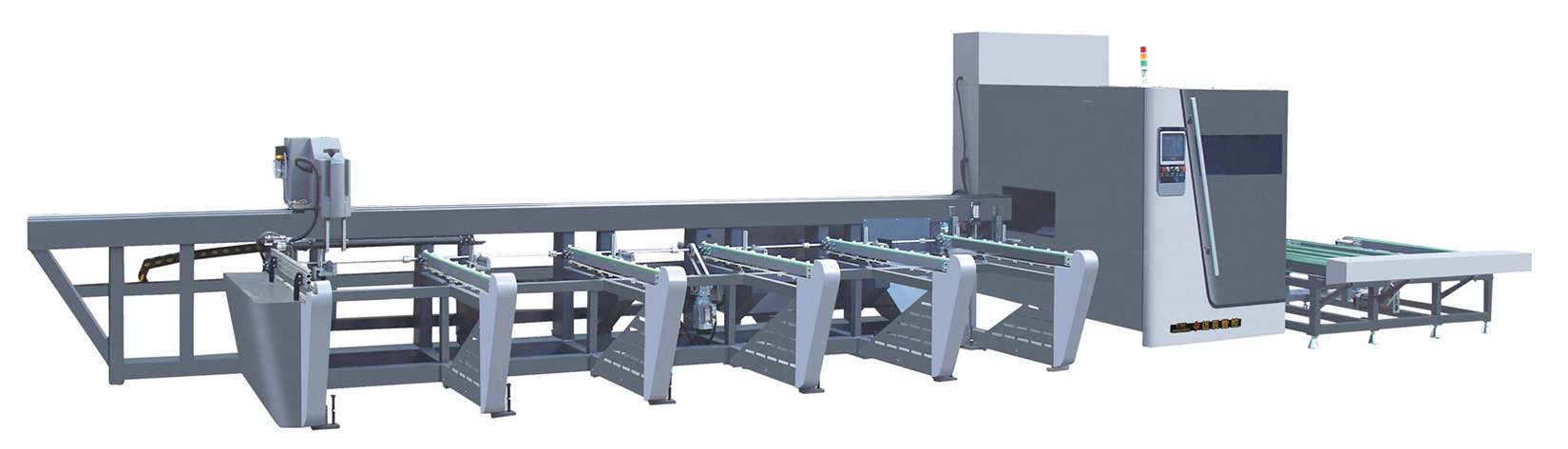

Cutting Center for aluminum profile(economical model) MCJQ-500×6500

Performance Features

The cutting center is a new generation, which is widely used in thermal-broken aluminum doors and windows. By setting the working mode and size, the machine automatically completes the processes of automatic feeding and cutting, automatic sorting of scraps and fnished products by mechanical arm.

1. The cutting part of the machine is made by casting technology, one-piece structure, and then processed by horizontal machining center at one time, thus ensuring the accuracy of cutting and the concentricity of rotation. The feeding and discharging section are all welded with industrial rectangular steel tube, and then they are treated with professional aging treatment to remove internal stress. After CNC gantry processing, the tolerance is guaranteed to be 20μm, ensuring the feeding accuracy and the stability of the running speed. The rectangular steel tube and plate with 6mm thickness realize the perfect combination of mechanical stability and running speed.

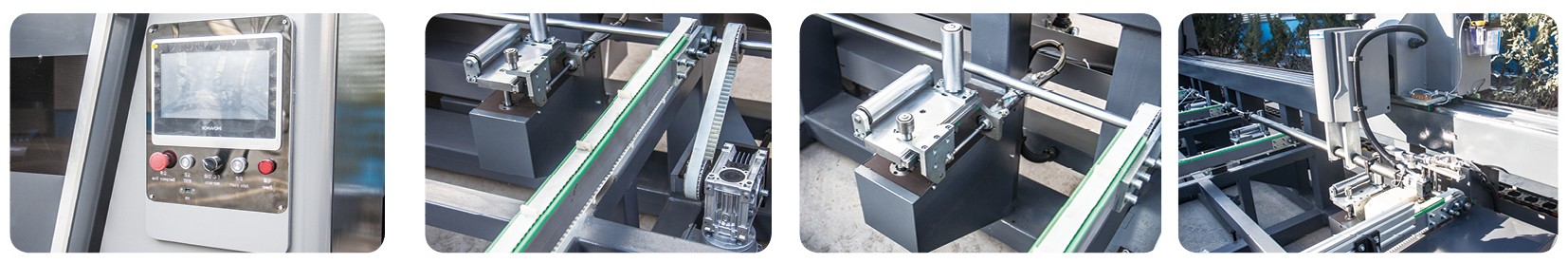

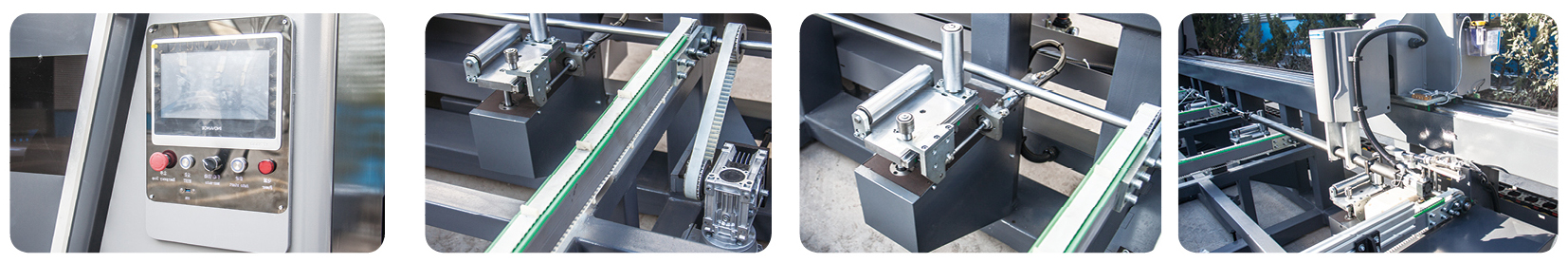

2. CNC control system adopts Han's SCM control system, which can connect optimization software and support multi-axis linkage. Man-machine interactive operating system, intuitive operating interface, easy switch between automatic and manual, one-button start, visual positioning of manipulator hand wheel, more convenient.

3. The whole profile can be automatically fed,cut and discharged. The whole process is closely coordinated, sensitive, safe and reliable. Equipped with automatic feeding mechanism to save labor. Equipped with standard clamping system, 45 and 90 degree cutting can be completed by one clamping with high accuracy.

4. It can automatically identify the length of the scrapped parts, and make different treatments according to the length of the left profile, so as to avoid hitting the profile.

5. Adopts Taiwan Dinghan guide rail and rack and high-strength ball screw. The shorter the shortest distance, the higher the accuracy, and the clamping method is more stable, which greatly improves the processing accuracy and product stability.

6. The manipulator has the function of profile inspection and automatic avoidance, which can effectively reduce wrong cutting and waste; The manipulator rotating device is more flexible and adaptable to the clamping of more profiles. With the hand wheel, visual manipulator positioning can be realized.

7. Optional chip removal machine can be installed to collect material heads to keep the working environment clean.

Technical Parameter

Input power | 380v/50Hz Three-phase four-wire system |

Operating air pressure | 0.6-0.8MPa |

Air consumption | About 200L/min |

Total power | Sawing spindle power: 3×3kW Servo power: 0.75KW*1, 0.85*1 Loading table motor power: 0.55KW |

Blade speeds | 15-35m/min |

Operating speed of manipulator | 40-80m/min |

Profile cutting range | Width 110mm Height 120mm |

Effective length of blank | 2400-6500mm |

Sawing length range | 400mm-6500mm |

Allowed loading quantity of loading table | 8+1 in cyclic feeding |

Blade size | Φ500mm×4.4mm×Φ30mm×120T |

cutting angle | 45°, -45°, 90° can be cut in any combination |

Spindle motor speed | Sawing spindle speed 3000r/min |

Discharge stroke of manipulator | About 1200mm |

Sawing length accuracy | ±0.2mm |

Sawing perpendicularity | ≤0.1mm |

Total weight | About 4.5 tons |

Overall dimensions (L× W× H) | 3500×3500×2200mm |

Packing Details

Company Profile

Shandong Maichen CNC Machinery Co.,LTD. is a leading enterprise in building Windows and doors and building glass industry, specializing in manufacturing complete sets of building energy-saving plastic windows and doors machines, aluminum alloy windows and doors machines, insulating glass machines, curtain wall machines. The company was founded in 2005, the products all over China's provinces, cities, autonomous regions, and exported to the United States, Europe, Russia, Nigeria, the United Arab Emirates, Brazil, India and other more than a dozen countries. We strictly in accordance with the ISO9001:2000 version of the international quality certification system, manufacturing quality, safety, standard of high quality products to get the best evaluation from customers, with good customer reputation to increase the annual turnover is our sales strategy.

The company has riveting welding workshop, mechanical processing, painting workshop, assembly workshop, exhibition hall, warehouse, covering an area of more than 30 mu, can be customized according to customer requirements and production needs of non-standard equipment. Precision mechanical parts, rigorous assembly attitude, perfect after-sales service for every customer escort. More than 30 kinds of aluminum window processing machines can complete the cutting, Angle group, drilling, punching, bending round process of aluminum profiles; More than 20 kinds of plastic doors and windows processing machines can complete plastic profiles cutting, welding, milling, cleaning procedures; More than 20 kinds of insulating glass processing machines and glass curtain wall machines can complete the cutting, cleaning, heating, gluing, cold pressing, edging, assembly and filling processes of slot-aluminum insulating glass or composite adhesive strip insulating glass. Due to the difference of production scale and efficiency, we can provide customers with the factory plan, cost accounting and the latest industry information according to the most reasonable set of industrial line assembly line operation according to your output ratio. In order to make your installation and use more safe, convenient, fast and efficient work, we have arranged professional engineers to do after-sales technical guidance, troubleshooting and other technical problems for you.

Our Advantages

· We provide professional window and door production solutions.

· Professional online service team, any mail or message will reply within 24 hours.

· We have a strong team provide wholehearted service to customer at any time.

· We insist on Customer is Supreme, Staff toward Happiness.

· Put the Quality as the first consideration;

· OEM & ODM, customized design/logo/brand and package are acceptable.

· Advanced production equipment, strict quality testing and control system to make sure superior quality.

· Competitive price: we are a professional window and door machine manufacturer in China, there is no middleman's profit, and you can get the most competitive price from us.

· Good quality: good quality can be guaranteed, it will help you keep the market share well.

· Fast delivery time: we have our own factory and professional manufacturer, which save your time to discuss with trading companies. We will try our best to meet your request.

SHANDONG MAICHEN CNC MACHINERY

SHANDONG MAICHEN CNC MACHINERY